BALLBAR TESTING & ANALYSIS

- Latest Bluetooth type Renishaw QC-20 Ballbar instrument.

- All 3 Planes ( XY,YZ & XZ) checking option

- Latest Renishaw software

Common problem faced during machining

Advantage of performing Ballbar Testing

- Analyze the problem in the machine and point out the contributing factor then solve it

- It is an instrument which sets the benchmark in interpolation checking in CNC machine.

- It is calibration test, which evaluate the result in just 30 minutes with data analysis.

- To know the Servo errors in Motors.

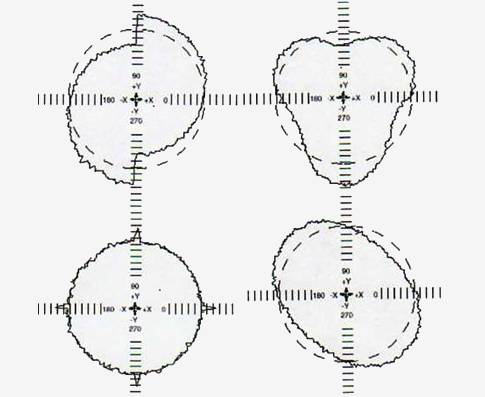

- To know approx. Geometrical errors contributing in circular interpolations

Why you need to Ballbar?

-

IT IS EFFECTIVE IN :

- Verify machine performance.

- Achieve manufacturing performance

- Machine condition monitoring

- New machine acceptance testing.

- Predictive maintenance