LASER CALIBRATION SERVICES

WHY SHOULD YOU DO LASER CALIBRATION:

- Solves the accuracy related problems more accurately with less time consumption.

- Analyse the mechanical issues in CNC machine assembly parts.

- Yearly & periodic calibrations will make you aware of machines updates,

- Instead of dial technology, check it now with highly accurate laser instrument for full stroke length.

- Check positional accuracy, repeatability and backlash in a more professional manner

- Important for internal and external audit of ISO and other such agencies.

- More importantly, to know the real accuracy of your machine.

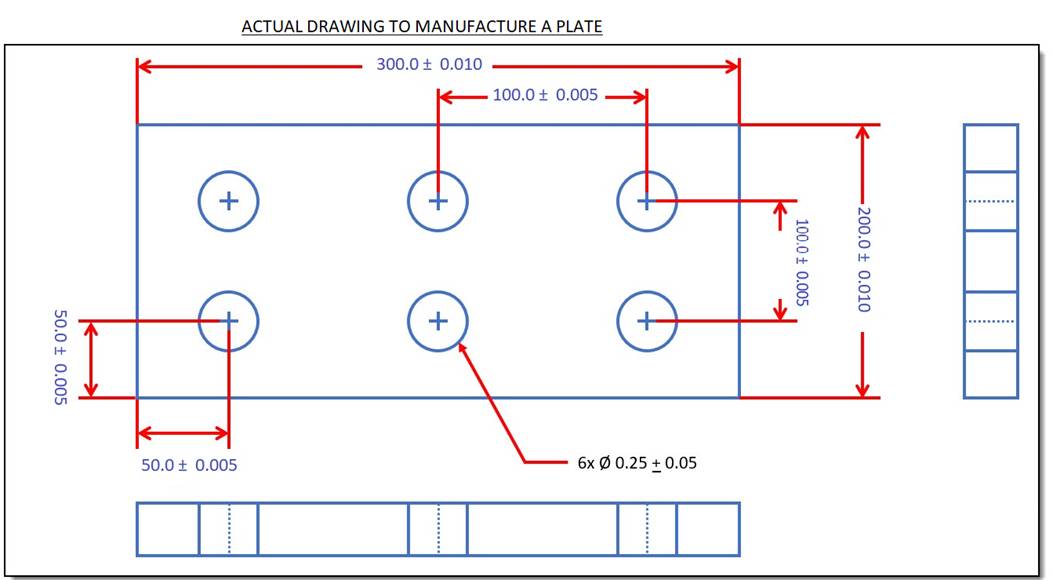

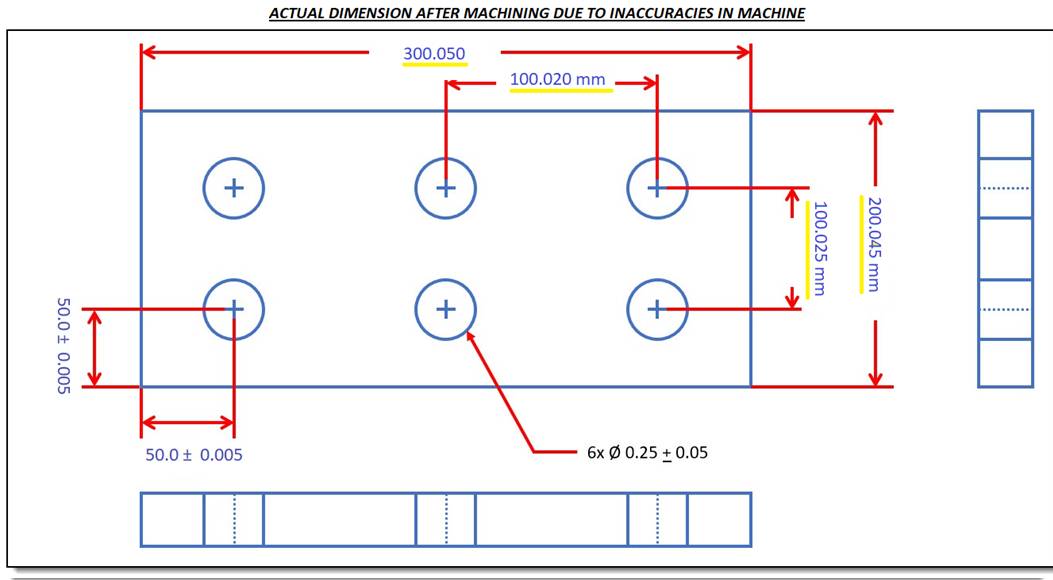

FEW EXAMPLES DRAWING ILLUSTRATING THE ERRORS

SO WITH LASER CALIBRATION & PITCH ERROR COMPENSATION THE DIMENSIONAL ERRORS CAN BE REDUCED.

ADVANTAGE SPUMATECH

- Having a good technical expertise of more than 22,000 machines calibrations which includes CNC VMC’s, CNC lathes, CNC SPM” s, CNC grinders and wide range of CNC machines.

- Right now, across Industries - Worldwide we are the fastest. Once the machine is handed over, we do the necessary Programming, Parametric Adjustment, to give the desired final accuracy.

- More importantly, If the problem is unsolved, we will give a detailed study report wherein our suggestion on exact part replacements which will reduce your expenditures of machine. We don’t guess instead we are precise in our judgement.

- We can do 3 to 4 small machines in a day; speed with accuracy is our MOTTO.

Instrument we have

- Renishaw XL-80 & XC-80 with environmental compensation unit.

- All accessories for Linear axis measurement & also for slant axis measurement.

- Latest Renishaw software.